Coating Production Line

-

Price Range: $1,000.00 - $30,000.00 / Set -

MOQ: 1 Set/Sets (Min. Order) -

Model Number: -

Lead Time:Quantity(Sets) 1 - 100 101 - 200 >200 Estimated Time(Days) 30 40 Negotiable -

Core strengths:1. 20 years manufacturer & trading company with powerful strength.

All Core Strengths

2. One stop solution provider.

3. OEM&ODM services are available.

4. Flexible payment terms:T/T,Cash,Western Union,L/C,etc.

- Tel +86 13838293687

- Email gm@yuedatech.com

Product description:

The coating industry is currently a key industry in the world, and its equipment investment accounts for 30% of the total production equipment investment. Obviously, its development has strong influences on the changes in contemporary China. With the improvement of China's economic level and the contact and exchange with the world's advanced industrial technology, the coating technology has developed by leaps and bounds in China, and the automatic coating production and the involvement of some advanced technologies have promoted the technical and artistic quality of coating technology. At the same time, advanced technologies in electrostatic coating, electrophoretic coating, powder spraying and other industries have been well promoted and applied in China, and its coating industry is thriving. These advanced coating technologies are widely used in the home appliance industry, steel furniture industry, automobile industry, daily hardware industry and other fields of people's daily life, and the current coating technology not only has the basic anti-corrosion effect, but also shows its beautiful and colorful side. In addition, with the combination of painting equipment and automatic conveying, the production efficiency of coating is also improved significantly.

In recent years, due to the aggravation of air pollution, small-scale coating and open-air spraying have been strictly regulated by the government, and the water-retrieving painting booth with high-efficiency paint mist treatment capacity has attracted the attention of the majority of small and medium-sized enterprises.

Water-retrieving painting booth:

In the field of industrial coating, spraying work shall be carried out in an operation room with the forced air supply and exhaust and mist spraying ventilation device as well as favorable lighting and fire fighting facilities, and the operation room is called a spray booth. According to different performances and functions, the spray booth is classified into the Ω electrostatic spray booth, electrostatic spray booth, water-retrieving painting booth, Venturi spraying booth, water curtain spray booth and other water spray booth. The operation mode of upper air supply and lower air exhaust is adopted for the water-retrieving painting booth, to be exact, the outdoor air is purified by the air-conditioning blowing system and the filter materials at the top of the spray booth, and is then sent to the spray booth, flowing from top to bottom around the workpiece and operators. After that, the exhaust gas containing particulate matters produced in the work is quickly led into the water-retrieving machine below the floor grill through the ventilation action of the outdoor exhaust fan, and the water overflowing from the washing tray into the water-retrieving machine is atomized under the action of high-speed airflow and fully mixed with the airflow entering the water-retrieving machine, to collect most of the particles with the water; the purified airflow passes through the water surface and enters into the catchment area, and the separated water flows back into the circulating pool by gravity; the purified air is discharged to the high altitude outdoors by the exhaust fan. Though such reciprocating cycles, all particulate components in the air are effectively removed.

Movable spray booth:

Considering the difficulty in handling large workpieces in the spraying process, a movable spray booth is designed, achieving the same treatment effect of the water-retrieving spray booth through the cooperation of electric control system and machinery. It not only solves the problem of workpiece handling, but also enables the coating process to be carried out smoothly.

Water curtain spray booth:

Mobile spray paint room to solve the transportation of ultra-large workpiece inconvenience

The spraying work shall be carried out in an operation room with the forced air supply and exhaust and mist spraying ventilation device as well as favorable lighting and fire fighting facilities, and the operation room is called a spray booth. According to users' requirements for workpiece coating and paint mist treatment, the water curtain spray booth is developed by our company.

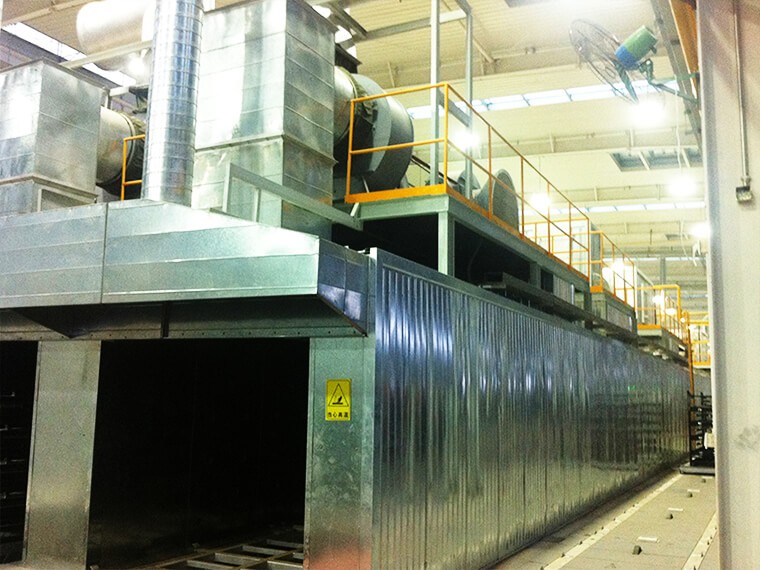

Drying room:

In order to accelerate the coating curing into film, so that the product coating more durable, bright and beautiful color, according to the coating process and plane layout needs, drying room generally according to the use, structure, heat source and heating mode classification. Such as the use of gas fuel, oil, electricity, steam heating bridge, through, n, box, multi-stroke hot air convection drying room, far infrared drying room, both combined drying room

| Transfer vehicle main technical parameters | |

| Dimension(mm) | 11000-14000mm(length), 3500mm(width), 575mm(height) |

| Travelling speed | 5-38m/min |

| Max load capacity | 15T |

| Travelling motor power | 5.5KW |

| Reducer(K series) | 45.16r/min |

| Frequency inverter | FR-E700 |

| Driving wheel diameter | φ375 |

Welcome your inquiry, welcome to visit us. One stop solution is ready for you!