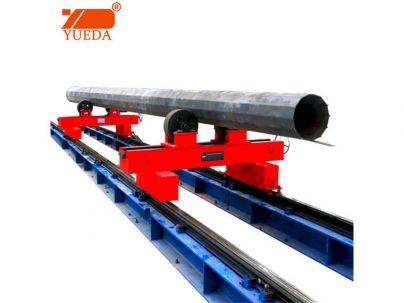

Yueda brand automatic rotating welding positioner

-

Price Range: $1,000.00 - $30,000.00 / Set -

MOQ: 1 Set/Sets (Min. Order) -

Model Number:- All Options

- ZHB1

- ZHB3

- ZHB6

- ZHB10

- ZHB20

- ZHB30

- ZHB60

- ZHB100

- ZHB150

- ZHB200

-

Lead Time:Quantity(Sets) 1 - 100 101 - 200 >200 Estimated Time(Days) 30 40 Negotiable -

Core strengths:1. 20 years manufacturer & trading company with powerful strength.

All Core Strengths

2. One stop solution provider.

3. OEM&ODM services are available.

4. Flexible payment terms:T/T,Cash,Western Union,L/C,etc.

- Tel +86 13838293687

- Email gm@yuedatech.com

Yueda brand automatic rotating welding positioner

Product description of Yueda brand automatic rotating welding positioner:

Welding positioner also named as welding rotating worktable, which is mainly used for welding and assembling parts, It makes the workpiece in the best welding or assembly position through the turning over of the mechanism for welding and assembly. It is widely used in the welding of flange and pipe fitting joints, as well as the inversion of construction machinery and the position conversion of various welding structures. It can also be used as robot peripheral equipment to realize welding automation. It greatly improve the quality of welding, at the same time can reduce the number of work handling, reduce the labor intensity of workers, quickly improve the labor efficiency.

The welding positioner series are side tipping type, head and tail rotation type, head and tail lifting rotation type, head and tail inclined type and double rotation type,etc. Special customized welding rotating worktable are available to meet clients' different requirement.

Features and advantages of Yueda brand automatic rotating welding positioner:

- 1. Different welding positioner with load capacity from 50kg to 200Ton, with electric type or hydraulic type, to meet client’s different requirement for welding positioner.

- 2. The welding positioner with pedestal structure, and the worktable adopts AC frequency conversion stepless speed regulation, with uniform rotation speed and no crawling, meet the requirement of welding workpiece for the speed of rotation.

- 3. The frame is made of section steel and steel plate, with reasonable structural design and good bending and torsion resistance.

- 4. The work table surface is a circular structure, which is processed with equidistant concentric circles. The radial T-slot (T-bolt) is processed on the table, which is convenient for alignment of workpiece and easy to install all kinds of positioning and clamping tools.

- 5. The tilting mechanism adopts worm reducer with self-locking function and brake motor to realize double braking function to ensure the safe and stable operation of the reducer in the tilting process.

- 6. A conductive device is installed under the work table to form a good conductive circuit of welded ground wire, so as to avoid over-electricity of rotary support, which will affect its service life.

- 7. Equipped with different control modes: electric control cabinet, pendent control or remote control.

- 8. Electrical components are famous brands at home and abroad, using frequency stepless speed control, high operating accuracy, smooth operation, with multiple protection functions such as overvoltage, over current, overload, overheating, etc.

-

Any interest? Welcome to contact us to get details and professional quotation! OEM&ODM service are available!

| Yueda brand automatic rotating welding positioner main parameters | |||||||||||

| Model | ZHB1 | ZHB3 | ZHB6 | ZHB10 | ZHB20 | ZHB30 | ZHB60 | ZHB100 | ZHB150 | ZHB200 | |

| Rated loading capacity(kg) | 100 | 300 | 600 | 1000 | 2000 | 3000 | 6000 | 10000 | 15000 | 20000 | |

| Rotation speed(rpm) | 0.2-2 | 0.1-1 | 0.05-0.5 | 0.05-0.5 | 0.05-0.5 | 0.05-0.5 | 0.05-0.5 | 0.02-0.2 | 0.02-0.2 | 0.028-0.28 | |

| Tilting speed(rpm) | manual | ≈0.3 | ≈0.3 | ≈0.3 | ≈0.3 | ≈0.2 | ≈0.2 | ≈0.2 | ≈0.2 | ≈0.2 | |

| Worktable diameter(mm) | ∅300 | ∅600 | ∅800 | ∅1000 | ∅1200 | ∅1400 | ∅1500 | ∅2000 | ∅2000 | ∅2500 | |

| Max eccentric distance(mm) | 100 | 100 | 100 | 100 | 150 | 150 | 180 | 200 | 250 | 200 | |

| Max Gravity center distance(mm) | 200 | 200 | 300 | 300 | 300 | 300 | 210 | 400 | 450 | 630 | |

| Worktable tilting degree(°) | 0-90 | 0-90 | 0-90 | 0-120 | 0-120 | 0-120 | 0-120 | 0-120 | 0-120 | 0-120 | |

| Rotation power(kw) | 0.09 | 0.18 | 0.37 | 0.37 | 0.75 | 1.5 | 2.2 | 3 | 4 | 4 | |

| Tilting power(kw) | manual | 0.25 | 0.37 | 0.75 | 1.5 | 2.2 | 3 | 4 | 7.5 | 7.5 | |

| Max rotation dia. At 90°(mm) | ≤450 | ≤850 | ≤1250 | ≤1700 | ≤2000 | ≤2400 | ≤2800 | ≤3200 | ≤3500 | ≤3500 | |

| Dimension | Length(L) | 460 | 1000 | 1000 | 1440 | 1650 | 2120 | 2400 | 2850 | 3360 | 3810 |

| Width(W) | 382 | 800 | 820 | 1060 | 1200 | 1400 | 1500 | 2000 | 2230 | 2500 | |

| Height(H) | 400 | 650 | 880 | 1057 | 1220 | 1465 | 1660 | 1939 | 2095 | 2098 | |

Welcome your inquiry, welcome to visit us. One stop solution is ready for you!